DIGITAL INKJET PRINT ON GLASS PLATES

The combination of specific UV curable inks, Jet primer and UV light system developed by AX (Aroja Xorfex) is the way of success in high adhesion and resistance of print on various materials. Successfully has been printed following materials: METALS (aluminum, stainless steel, painted steel.. ), PLASTIC (PVC, PE.. ), GLASS, CERAMICS, PAPER, WOOD, etc.

The digital ink-jet technology is developed for print of spot PANTONE colors.

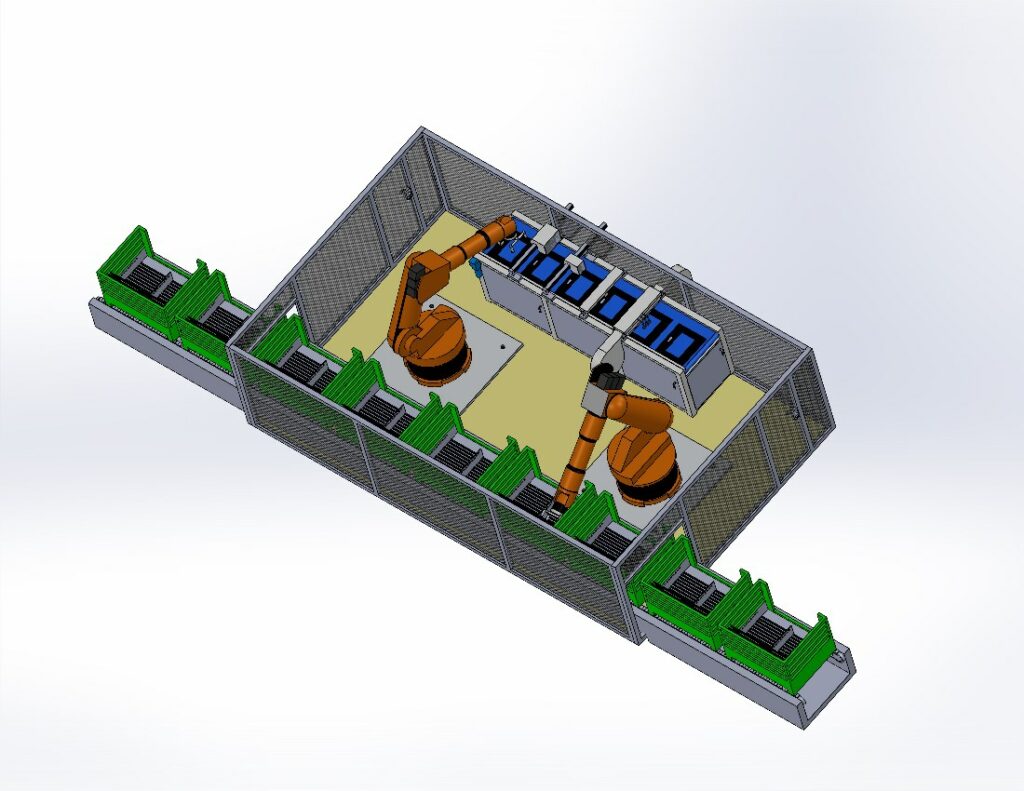

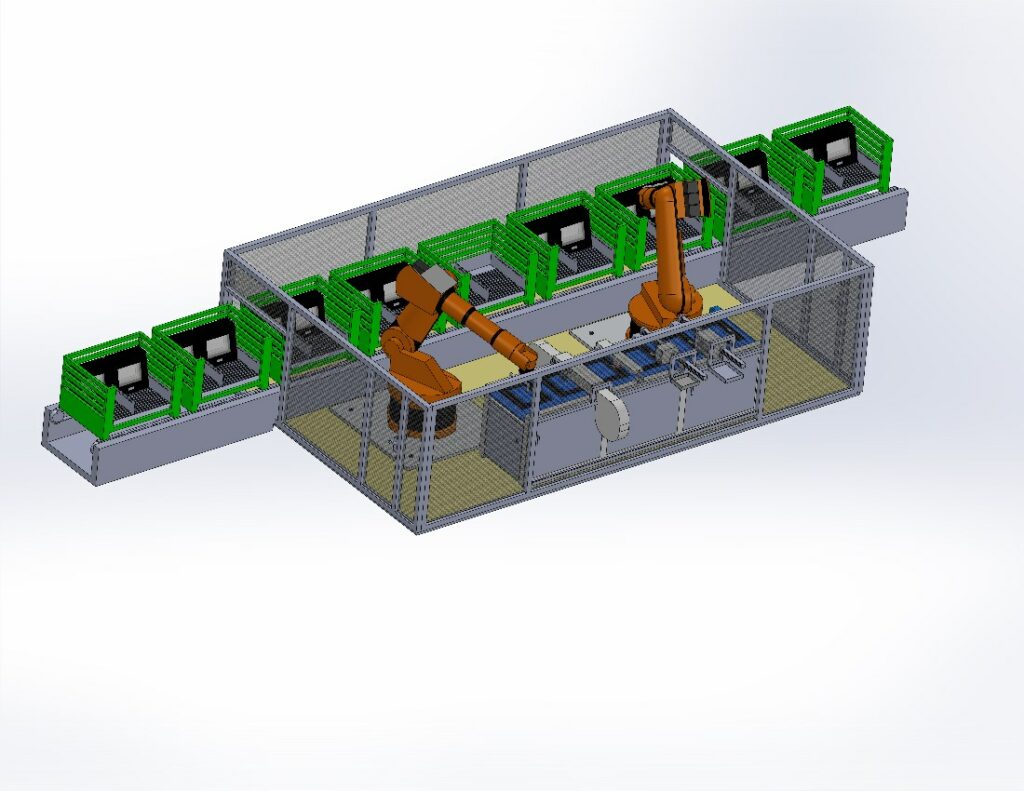

The requested device is a modified machine designed for very fast printing on panels up to size 550x600mm. The basic element is an advanced print module fitted with one row of print heads KM1024iMHE 10x for colors and for primer KM1024iLHE for primer 2x. One-color carriage uses up to six colors and a maximum of 12 printing heads. On side of this module is a UV curing lamp. If necessary the machine is able to apply ink-jet primer by secondary print module. This print carriage is designed up to six secondary printing heads and is equipped with an IR lamp for the fast drying of primer.

UV curable ink exhibits adhesion to a wide range of materials and also easy maintenance of print heads and therefore easy maintenance of the whole machine will be used for printing. Part of the machine will be an electronically regulated UV lamp cooled by air. After curing, the UV ink becomes instantly abrasion resistant and it is immediately possible to further work with the material.

SOLUTION OF THE PRINT MODULES

- The construction of the machine and printing modules is designed as a welded frame with a pull-out print module for easy maintenance and control of the print heads. The print is done by several runs over the surface of the panel. The print module is adapted to move in Z-axis in order to cover different heights of printed panels.

- The maximal printing speed of printing head KM1024iMHE is 160 m/min.

- The time needed for the print of one panel will be between 20 – 30 seconds for one site. If double side print needed the print time will be double.